- Home

-

Appliance Type

- Dehumidifier Parts & Accessories

- Dishwasher Parts & Accessories

- Dryer Parts & Accessories

- Freezer Parts & Accessories

- Garbage Disposal Parts & Accessories

- Griddle Parts & Accessories

- Hoods Parts & Accessories

- Ice Machine Parts & Accessories

- Microwave Parts & Accessories

- Oven, Range & Stove Parts & Accessories

- Refrigerator Parts & Accessories

- Trash Compactor Parts & Accessories

- Washer Parts & Accessories

- Air Conditioner Parts & Accessories

-

Brand

- Admiral Parts & Accessories

- Amana Parts & Accessories

- Bosch Parts & Accessories

- Caloric Parts & Accessories

- Crosley Parts & Accessories

- Dacor Parts & Accessories

- Dynasty Parts & Accessories

- Electrolux Parts & Accessories

- Estate Parts & Accessories

- Frigidaire Parts & Accessories

- Gaggenau Parts & Accessories

- General Electric Parts & Accessories

- Gibson Parts & Accessories

- Hoover Parts & Accessories

- Jade Parts & Accessories

- Jenn-Air Parts & Accessories

- Julien Parts & Accessories

- Kelvinator Parts & Accessories

- Kenmore-Sears Parts & Accessories

- KitchenAid Parts & Accessories

- LG Parts & Accessories

- Magic Chef Parts & Accessories

- Maytag Parts & Accessories

- Norge Parts & Accessories

- Roper Parts & Accessories

- Samsung Parts & Accessories

- Speed Queen Parts & Accessories

- Tappan Parts & Accessories

- Thermador Parts & Accessories

- Whirlpool Parts & Accessories

- White Westinghouse Parts & Accessories

Dryer drum rollers & pulleys

Whirlpool Drum Support Roller 12001541

Regular Price: $31.00

Compare At: $8.00

You Save: $23.00

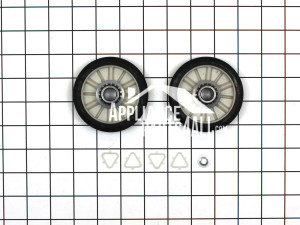

Whirlpool Rear Drum Support Roller Kit 349241T

Regular Price: $21.00

Compare At: $7.00

You Save: $14.00

Whirlpool Drum Support Roller WP37001042

Regular Price: $14.00

Compare At: $8.00

You Save: $6.00

Whirlpool Dryer Drum Roller Axle WP6-3129480

Regular Price: $11.00

Compare At: $4.00

You Save: $7.00

Whirlpool Belt Tension Pulley WP6-3700340

Regular Price: $18.00

Compare At: $8.00

You Save: $10.00

Whirlpool Belt Tension Pulley WPY54414

Regular Price: $13.00

Compare At: $7.00

You Save: $6.00

Whirlpool Idler Pulley WP691366

Regular Price: $17.00

Compare At: $6.00

You Save: $11.00

Whirlpool Motor Pulley WP8066184

Regular Price: $38.00

Compare At: $20.00

You Save: $18.00

General Electric Idler Pulley WE12X81

Regular Price: $31.00

Compare At: $10.00

You Save: $21.00

Whirlpool Idler Pulley WP31001344

Regular Price: $37.00

Compare At: $21.00

You Save: $16.00

General Electric Idler Pulley WE12X83

Regular Price: $24.00

Compare At: $19.00

You Save: $5.00

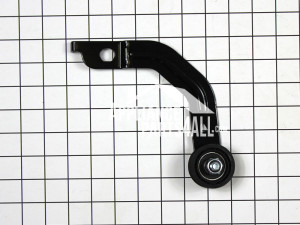

Whirlpool Idler Pulley Arm WP6-3705180

Regular Price: $45.00

Compare At: $25.00

You Save: $20.00

Whirlpool Drum Support Roller WPW10314173

Regular Price: $18.00

Compare At: $7.00

You Save: $11.00

Frigidaire Roller 5304523152

Regular Price: $21.00

Compare At: $15.00

You Save: $6.00

Whirlpool Idler Pulley WPW10344192

Regular Price: $71.00

Compare At: $40.00

You Save: $31.00

Whirlpool Motor Pulley W10837625

Regular Price: $68.00

Compare At: $36.00

You Save: $32.00

Bosch Drum Support Roller 00422200

Regular Price: $29.00

Compare At: $26.00

You Save: $3.00

LG Idler Pulley 4560EL3001A

Regular Price: $16.00

Compare At: $13.00

You Save: $3.00

Whirlpool Motor Pulley WP8544739

Regular Price: $72.00

Compare At: $32.00

You Save: $40.00

Samsung Drum Support Roller Assembly DC97-16782A

Regular Price: $43.00

Compare At: $31.00

You Save: $12.00

Whirlpool Motor Pulley WPW10136930

Regular Price: $71.00

Compare At: $41.00

You Save: $30.00

Frigidaire Idler Pulley 5304506264

Regular Price: $73.99

Compare At: $52.99

You Save: $21.00

General Electric Transmission Pulley WH38X10018

Regular Price: $16.00

Compare At: $13.00

You Save: $3.00

General Electric Idler Pulley WH7X115

Regular Price: $102.99

Compare At: $61.99

You Save: $41.00

General Electric Idler Assembly WE12X10019

Regular Price: $20.00

Compare At: $16.00

You Save: $4.00

General Electric Motor and Pulley Assembly WE17M67

Regular Price: $325.00

Compare At: $189.00

You Save: $136.00

General Electric Idler and Pulley Assembly WE01X10071

Regular Price: $75.99

Compare At: $46.99

You Save: $29.00

General Electric Wheel Roller WE03X10016

Regular Price: $37.00

Compare At: $18.00

You Save: $19.00

General Electric Drum Support Roller with Axle WE03X10008

Regular Price: $74.00

Compare At: $40.00

You Save: $34.00

General Electric Drive Pulley Set WH01X10608

Regular Price: $52.00

Compare At: $41.00

You Save: $11.00

Dryer Drum Rollers and Pulleys: The Unsung Heroes of Laundry Day

Dryer operation relies on a complex interplay of parts. Drum rollers and pulleys are two seemingly simple components that play a vital role in keeping your clothes tumbling and drying efficiently.

Together, they ensure smooth drum rotation and efficient drying. Replacing dryer rollers improves the device's effectiveness. Maintaining your dryer rollers and pulleys is vital for performance and longevity. Thus, it is critical to change cracked parts.

Role of Dryer Drum Rollers and Pulleys

Rollers are small wheel-like elements mounted on the shaft running through the drum's center. As the drum rotates, rollers support its weight and ensure smooth movement. A worn-out dryer roller kit leads to loud noises or even belt slippage. Pulleys are grooved wheels that route the belt, transferring power from the motor to the drum. Worn or misaligned dryer pulleys cause belt slippage, hindering proper rotation.

Signs of Damaged Rollers and Pulleys

Once a working dryer decides to provide damp clothes and work with strange noises, it catches some problems from this list:

- The squeaking. A squeak often points to worn-out or misaligned rollers, especially during the initial spin. A roller struggles to handle the weight, causing friction and squeaky protests.

- The wobbling. It can signify misaligned pulleys that lose their grip.

- The grinding. This sound typically indicates worn bearings.

These are just some clues suggesting your device needs you to change its details. If you hear these cries for help, don't ignore them!

The Benefits of Using OEM Parts

When it comes to changing broken parts, remember – quality matters. A genuine drum roller dryer is designed and manufactured specifically for your device. Authentic parts are highly durable, as they can withstand even harsh conditions. Using a suitable dryer drum roller guarantees your dryer maintains its original performance.

Choosing genuine parts comes with manufacturer warranties and support. Knowing your dryer is backed by the original details brings peace of mind to your laundry routine. While generic parts might seem cheaper, they disrupt your dryer's performance.

Maintenance Tips for Drum Rollers and Pulleys

Dryer's smooth operation relies on regular maintenance. Inspect it once in a few weeks. Listen for roller dryer machine changes in the usual hum, like squeaks, grinds, or wobbles. Provide regular visual checks, as early detection means timely action, preventing significant problems.

Regularly clean the lint filter and avoid overloading. Uneven distribution stresses the device, leading to premature depreciation.

Changing Drum Rollers and Pulleys: General Guideline

Always unplug the dryer before any repairs. If you are unsure of the steps below, call the local technician to replace the broken part:

- Access the needed part. Unplug the device and move it to a clear workspace. Remove the access panel so you can get inside the device.

- Release the belt tension. Find the dryer tensioner pulley and release it.

- Remove the drum. Check the device’s instructions; this action differs depending on the model.

- Replace the worn parts. Identify the worn parts and unscrew them. Carefully install the new ones.

- Reassemble the device. Reverse the steps above, reinstall the drum, attach the belt, and tighten the dryer belt tension pulley.

- Perform a test run. Run a test cycle to check whether everything is functioning smoothly. Listen for any suspicious noises or vibrations.

How To Find Perfect Details For Your Dryer

Replacing worn-out drum rollers and pulleys is crucial for running your dryer efficiently. But with so many available parts, figuring out which ones are right for your appliance can take time and effort. Here's a guide to help you navigate the selection process.

It’s easy to determine a model number as you can find this information printed as a sticker on the front or the back panel. Another place to find this number is the user manual. While researching for needed parts, consider their material, size, and number of grooves.

A dryer roller is typically made of nylon or rubber, while pulleys are mostly metal or nylon. Ensure the new parts match. Some pulleys have single or double grooves, depending on the belt. Make sure your new pulley matches the existing groove configuration.

ApplianceParts4All: Your Best Shop for Spare Parts

We understand that it is hard to find needed components. We also realize the importance of finding the authentic dryer’s drum rollers. That's why we sell only authentic parts.

Our friendly team is always happy to help you find the proper dryer roll and pulley. We offer competitive prices, ensuring you get the best value for your money.

Safety Precautions

Remember to prioritize yourself and your safety. Double-check the details after assembling the device. Even minor misalignment can cause a fatal break. Call the technician if you can’t determine whether you can fix the device.

Run a test cycle and listen for unusual noises. If you hear something suspicious, call the technician. It will be better to spend $100-150 for repair instead of buying a new dryer for $700+.

In Conclusion, Look Only For Genuine Roller Dryer Parts

These two components may look insignificant. However, they are one of the most essential parts of the dryer. If they break, the device stops working.

The easiest way to provide one's peace of mind is to buy only authentic details. Genuine components are engineered specifically for your dryer and provide seamless compatibility. You will usually get the manufacturer's warranty if you let a certified technician install these details.